Overview

Test Platforms

- Test cell for hydrogen permeation

- Autoclave for H2 material compatibility determination of samples

- Ejector test stand

- PEM-Single cell test stand

- PEM Stack test stand

- FC cathode sub system test stand

- Sampling system for the analysis of gas quality at filling stations and in production processes

- Calibration standard for hydrogen dispensers

- EHC electrochemical compression test stand "HERON"

Test Beds

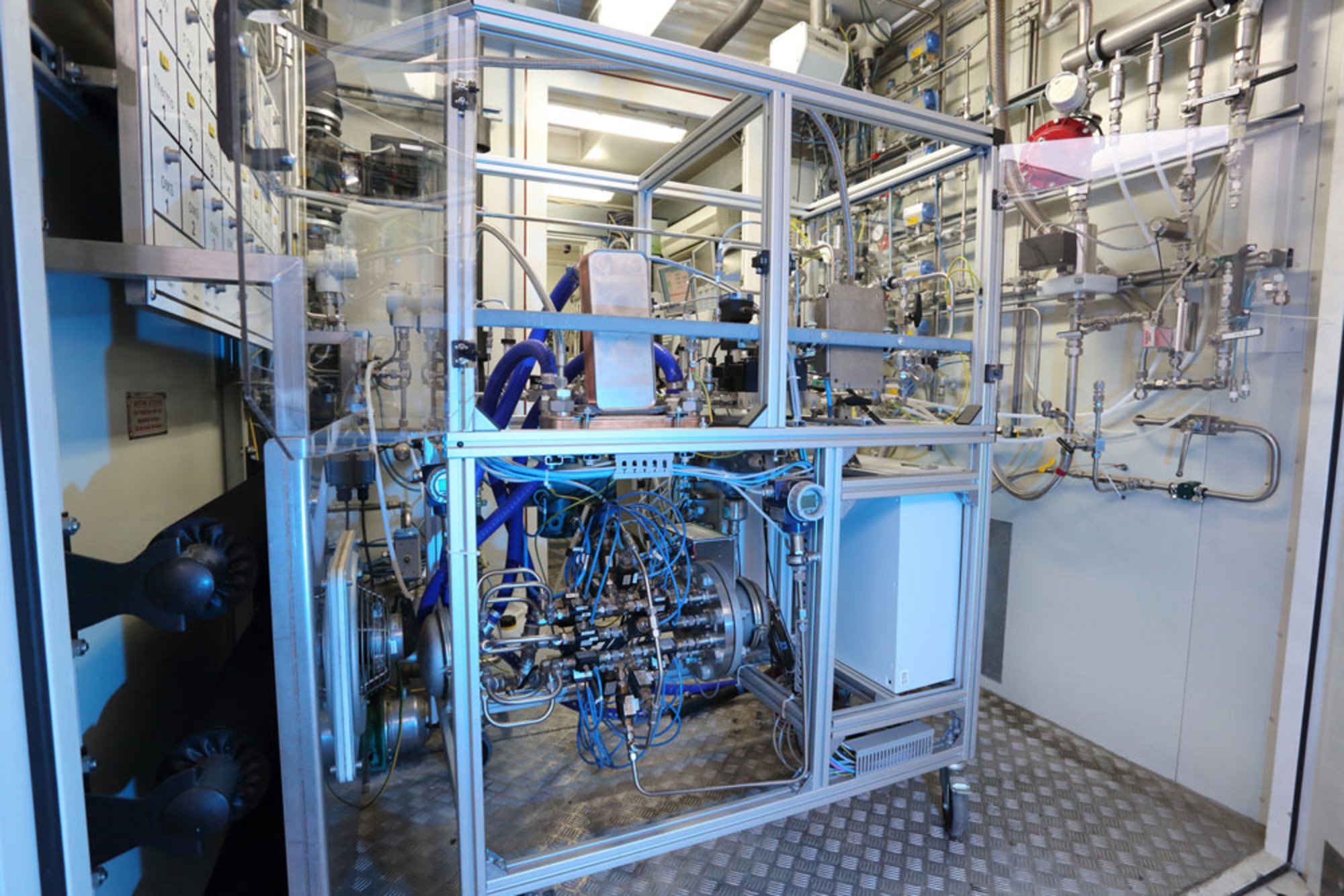

"Pascal" high-pressure test stand

The multifunctional test stand is used for testing hydrogen components and hydrogen systems in which compressed gaseous hydrogen up to 890 bar is used.

It is possible to carry out functional tests on test items, such as filling or emptying processes, endurance tests, pressure cycle tests, tests for internal and external leakage. All tests can be carried out at conditioned ambient conditions from -30 °C to +70 °C. Furthermore, a direct outlet of the 700-bar dispenser "Grot" is integrated, whereby refuelling tests can also be included by means of the measuring technology of the test stand.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

“Deimann" and "Troostwijk" component test stands

The "Deimann" and "Troostwijk" component test stands are used for testing hydrogen-carrying components and hydrogen systems in which compressed gaseous hydrogen is used up to 300 bar.

It is possible to carry out functional tests on test items and components, such as performance tests, filling or venting processes, endurance tests, pressure cycle tests, tests for internal and external leakage.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

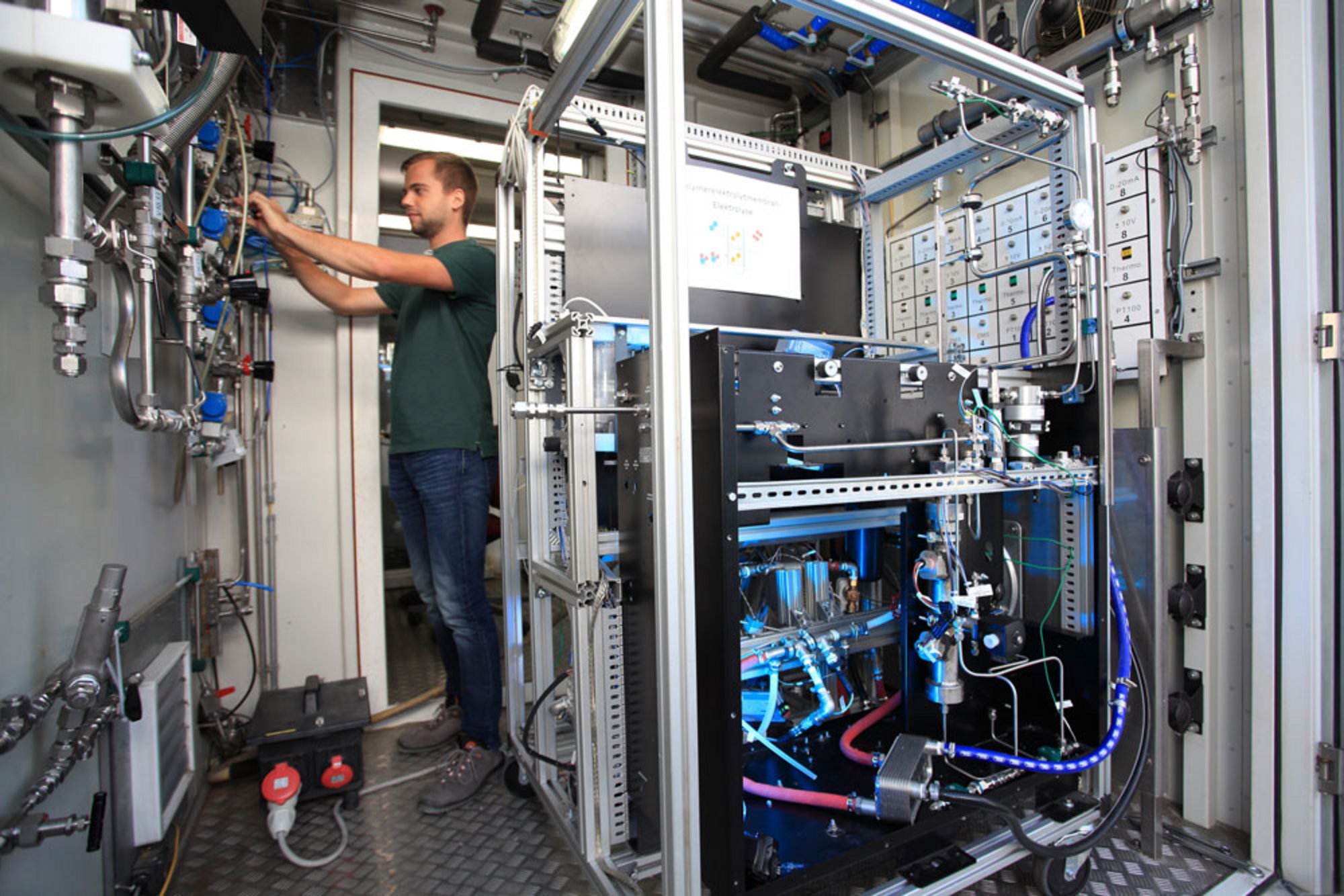

Fuel cell system test stand "Schönbein”

The HyCentA fuel cell system test stand is one of the most advanced test facilities for fuel cell systems worldwide that is freely accessible for research purposes. It uses the latest AVL PUMA OPEN Fuel Cell test software and offers a wide variety of measurement systems. This automation system in combination with the highly dynamic infrastructure ensures the highest flexibility within testing with freely parameterizable test runs. This high flexibility and the dynamic of the test stand support fuel cell system tests from auxiliary power units to highly dynamic automotive systems. In addition, the test stand enables testing from prototypes up to production systems, within a netto-power range from 3 kW up to 160 kW system power. The testing scale ranges from stationary as well as dynamic characterisation tests to accelerated stress tests or automotive tests under real world conditions. Ambient conditions and media supply temperatures can be dynamically adjusted in the range of - 40 °C to 85 °C. In addition, the humidity of the cathode can be varied in the range from 5 % to 95 % RH. The test stand enables research and development on topics ranging from energy management to thermal management, from the entire vehicle to the control and calibration of subsystems, from vehicle integration to the study of dynamics, cold start and durability. Thanks to the experienced staff, a wide variety of tests is possible and customised test solutions can be guaranteed.

Test and research portfolio at Schönbein:

- Optimization / calibration of FC systems / automated calibration and DoE

- Performance characterization / acceptance testing

- Reliability and durability testing

- Energy and thermal management / loss Analysis of FC Systems

- Freeze-start and cold-start procedures

- Accelerated stress tests, degradation validation as well as state of health analysis

- Analysis and optimization of dynamic operation

- Potential analysis of operation strategies

- Gas analytics and exhaust water analysis

- HiL / model assisted testing

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

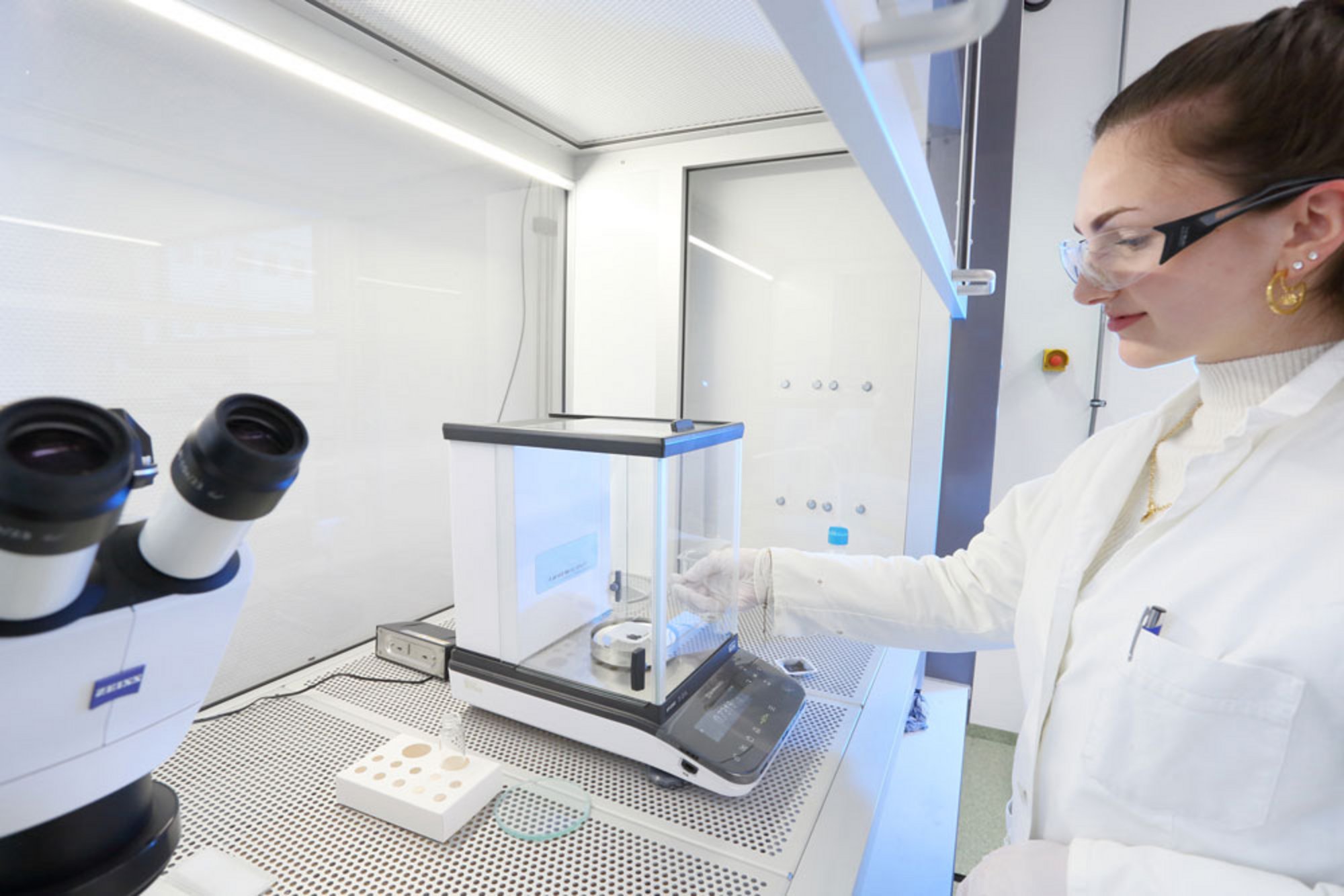

"Boltzmann" Analytical and Electrochemical Laboratory

The "Boltzmann" gas analysis laboratory is one of the most advanced H2 gas analysis laboratories in Europe. Core elements are the Fourier Transform Infrared Spectrometer (FTIR) and the Ion Molecule Reaction Mass Spectrometer (IMR-EI-MS). Our infrastructure enables high-precision analyses in the ppb range according to international standards (ISO 14687 Grade D, ISO 210872 and ISO 19880-8:20193 Annex E) for routine hydrogen quality analysis. A wide range of impurities can be detected to ensure reliable quality assurance among the entire hydrogen value chain in industry and H2 mobility. In addition, analyses of the compatibility of materials and components in hydrogen environment and their applicability in fuel cells and electrolysis technologies can be carried out in the laboratory. Furthermore, electrochemical test platforms are available in the laboratory for conducting tests on electrolysis cells and stacks as well as for testing electrochemical compression processes.

Test and research portfolio in the Boltzmann Laboratory:

- Analysis of hydrogen quality in the ppb range e.g. for PEM fuel cell applications.

- Wide range of components can be quantified (beyond ISO 14687:20191)1

- Monitoring and assessment of hydrogen quality for industry and end users

- Beyond the requirements of ISO 14687, we detect additional halogenated compounds, sulphur compounds, volatile hydrocarbons and other contaminants

- Analyses with a large number of carrier gases are possible: N2, H2, Ar, He, O2 and others

- Material characterisation to investigate the effect of hydrogen in microscopic scale

- Research platforms for electrolytic cell and stack tests and for testing electrochemical compression processes

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

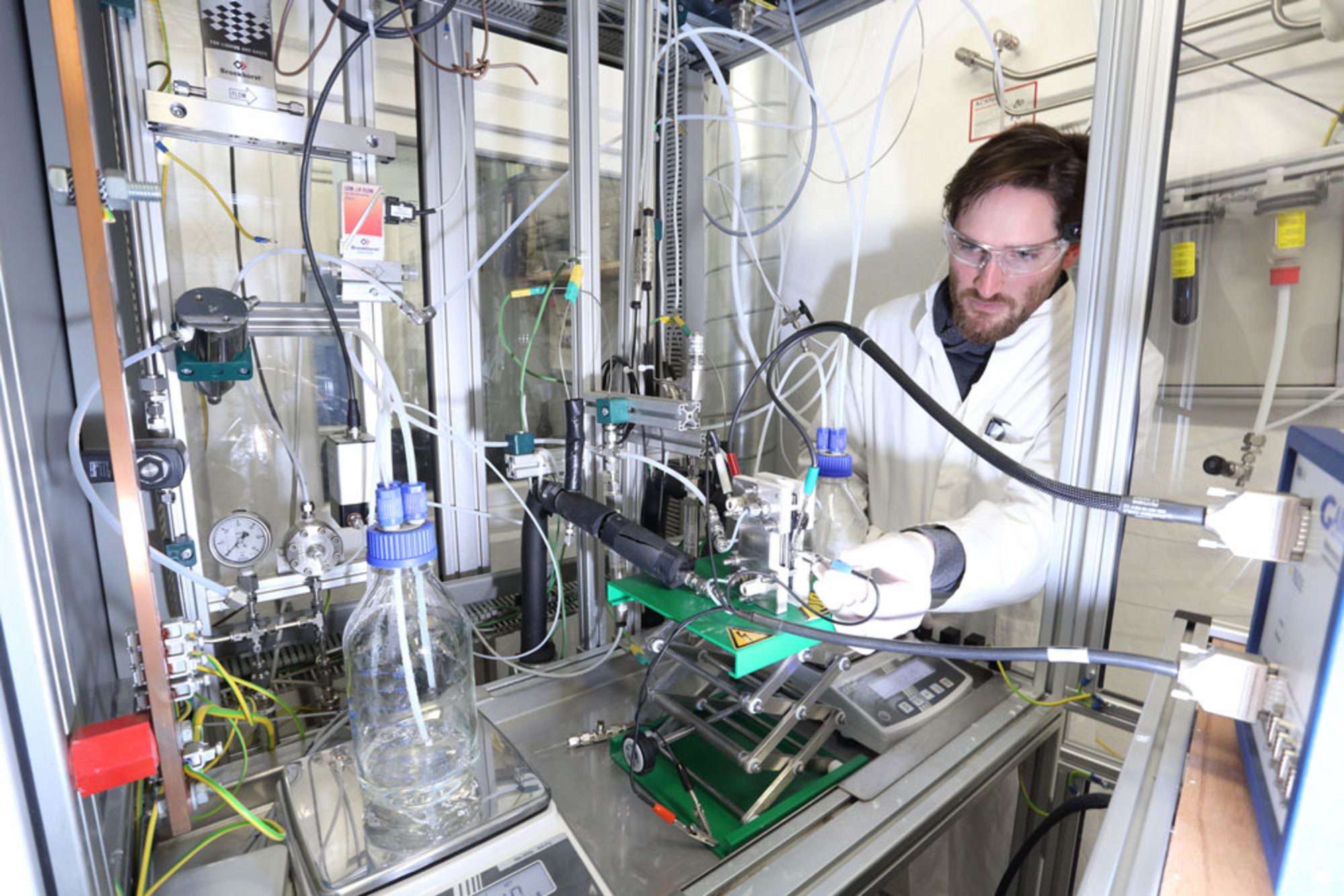

Electrochemical Analysis Laboratory "Faraday“

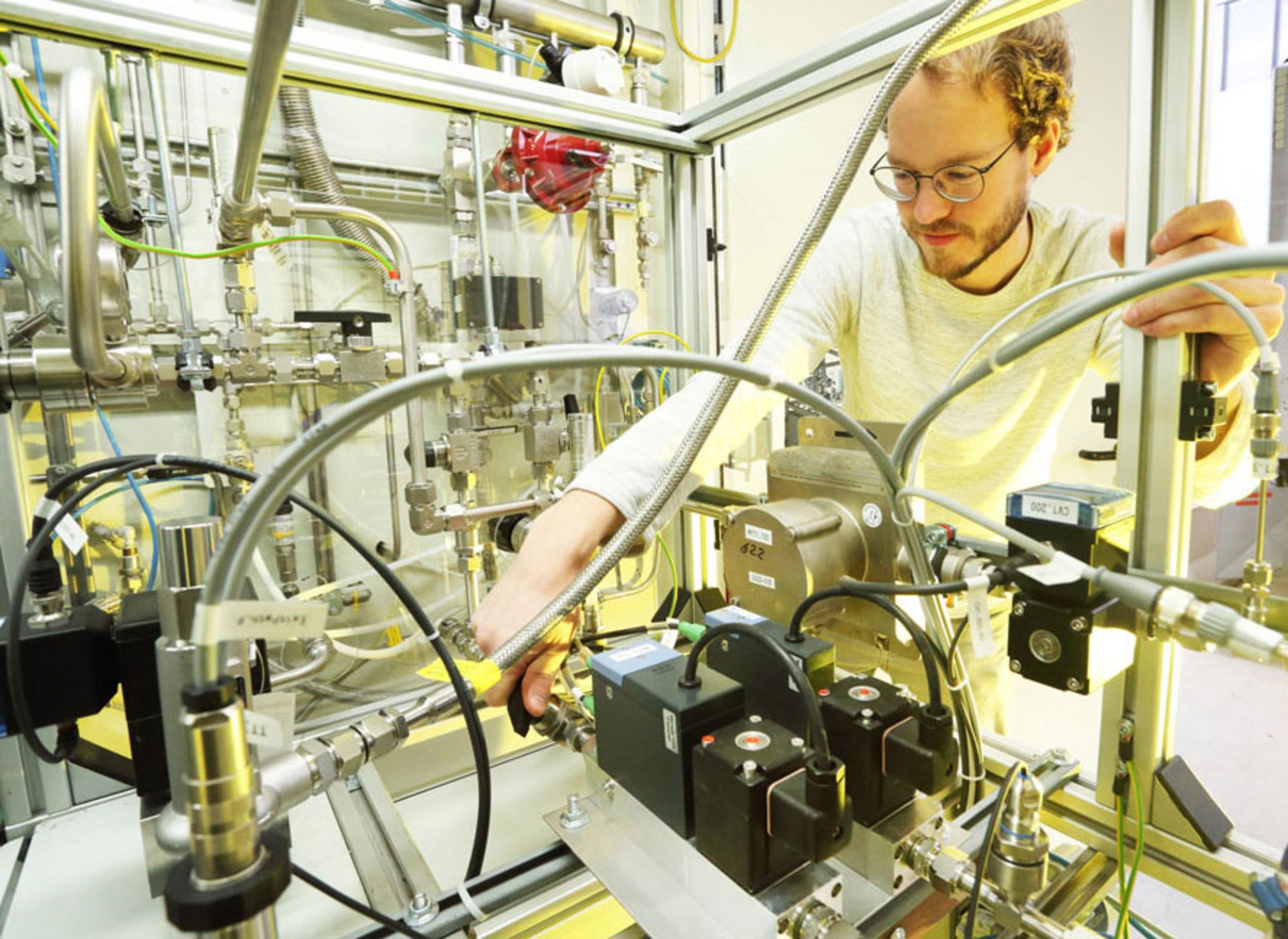

The "Faraday" electrochemical laboratory provides a research environment for the analysis and characterisation of hydrogen production and process technologies. A laboratory area is integrated into the lab for the assembly and chemical preparation of test items. The test rig controls the thermodynamic properties of the test item, including the flow rate, temperatures and pressures of the supply gases and liquids. The test rig includes an electrical source and sink that allow detailed characterisation by electrochemical impedance spectroscopy. A control room enables on-line data acquisition, monitoring and analysis for both short- and long-term experiments.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

Test Platforms

Test cell for hydrogen permeation

In the permeation test cell, a wide variety of polymer and plastic materials can be tested for their hydrogen permeability. Material characterisation is a decisive factor with regard to the efficiency, service life and safety of components. Plate samples of different thicknesses are clamped in the test set-up and exposed to hydrogen at a constant pressure of up to 1000 bar. In addition, the test cell can be tempered in the range from 0 °C to + 75 °C in order to investigate the temperature influence of permeability. The measurement process is fully automated and highly reproducible. The amount of permeated hydrogen is determined with the help of a carrier gas and precise measuring technology. In the course of a test, the permeation, solubility and diffusion coefficients of the material can be calculated. The permeation rates of the samples can be determined in the range of 10-9 bis 10-14molH2/cm/s/bar bestimmt werden.

Test and research portfolio of the test cell:

- Determination of permeation, solubility and diffusion coefficient of plate samples

- Recording of time-lag curves

- Measured values at pressures up to 1000 bar and temperatures in the range from 0 °C to + 75 °C

- Determination of the permeation rate in the range of 10-9 bis 10-14mol H2/cm/s/bar

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

Autoclave for H2 material compatibility determination of samples

Using two autoclaves with hydrogen atmospheres of up to 200 bar and 700 bar, it is possible to determine the hydrogen compatibility of material samples and components at the test centre. The tests are carried out for different hydrogen pressures and at different internal temperatures of the autoclave in order to be able to realistically simulate the conditions under which the materials are used. After several weeks of storage, the material is examined by means of different tensile tests at the Institute of Materials Science, Joining and Forming IMAT. The mechanical properties are determined after exposure to hydrogen and the material is checked for cracking and other possible signs of damage in order to assess its compatibility or incompatibility with hydrogen.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

Ejector test stand

The ejector test stand offers a wide range of test possibilities and a platform for the complete characterisation of ejectors, e.g. in fuel cells. One of the main advantages for the customer is that a wide range of boundary conditions for the ejector can be set and varied fully automatically, ensuring the function of the ejector in the anode path of the fuel cell system. The ejector test bench is fully automated and thus ensures rapid ejector investigations and optimisations.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

PEM-Single cell test stand

The PEM single cell test stand provides a research environment for the analysis and characterisation of hydrogen production and process technologies. A laboratory area is integrated into the infrastructure for the assembly and chemical preparation of the units under test (UUT). A test bench controls the thermodynamic properties of the UUT, including the flow rate, temperatures and pressures of the supply gases and liquids. The test bench includes an electrical source and sink that allow detailed characterisation by electrochemical impedance spectroscopy.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

PEM Stack test stand

The electrolysis stack test stand enables a comprehensive characterisation of electrolysis stacks with regard to their performance and degradation mechanisms. A comprehensive investigation of different operating conditions and parameters with regard to the influences on performance, safety and service life forms an important milestone for stack and system development. A key performance feature is the integration of the test bench into the high-performance infrastructure environment of the hydrogen test centre. This allows, for example, H2 online gas analysis to be implemented in test mode and EIS (electrical impedance spectroscopy) measurements to be carried out in-situ. These unique analysis possibilities combined with stack testing allow a comprehensive and detailed picture to be derived. Another key asset is our holistic understanding of the engineering of system, stack and cell and can thus significantly advance the design and development process on the basis of the test results. With the stack test stand, not only can the electrochemical behaviour be investigated via polarisation curves and impedance spectra, but also the hydrogen diffusion to the anode side and the water drag towards the cathode can be determined. With a power range of 1-15 kW at a maximum current of 450 A and a hydrogen pressure of up to 160 bar, the test stand covers a wide range from short stacks to small full stacks. With the flexible flow and temperature control on the anode side, a wide range of operating conditions between 0.1-10 l/min and 20-80 °C can be reproduced. Even the lowest partial load range can be reproduced thanks to the possibility of explosive atmospheres on the anode side.

Test and research portfolio at the test stand:

- Electrolysis stacks 1-15 kW maximum output

- Asymmetric pressure operation of the stacks

- Cathode pressure up to 160 bar

- Possibility for explosive atmospheres on the anode (incl. concentration measurement)

- Cell voltage monitoring for up to 16 cells

- Gas quality testing

- EIS measurement of the entire stack up to 60 V

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

Fuel cell cathode subsystem test platform

The cathode test platform provides a platform for testing individual components of the cathode subsystem as well as their combined performance and interaction in fuel cell systems of up to 150 kW power output. Key components to be tested include electric turbocharger (compressor and turbine), charge air cooler, membrane humidifier, droplet separator and valves in the air path. The water production and pressure drop of a fuel cell stack is being simulated by a specifically designed “stack simulator”, allowing tests to be performed under realistic conditions without the need to operate an actual fuel cell stack. A dedicated measurement and control system enables the integration of a wide variety of both inhouse and customer provided sensors and actuators for both high accuracy test results and comparative measurements.

Sampling system for the analysis of gas quality at filling stations and in production processes

The core element for seamless quality monitoring is high-purity sampling. For this purpose, we have specially developed an H2 sampling device that allows us to sample H2 along the entire process chain: Directly after the electrolysis, after purification and compression, at trailer filling/unloading or directly at the HRS. All processes up to the end application can be served with it. Here, the corresponding sampling know-how exists in order to be able to reliably detect the required detection limits in the ppb and ppm range for the corresponding gas components. In this respect, we combine analytical know-how of gas analysis with technical expertise for the entire production and use chain. This makes us a sought-after and valuable partner of the hydrogen economy.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

Calibration standard for hydrogen dispensers

The hydrogen quantity measuring device developed at HyCentA is used to calibrate hydrogen dispensers up to 700 bars in order to comply with the legal framework conditions for the public exchange of goods. The pVT measurement principle, which is used to determine the amount of hydrogen dispensed by the dispenser, is based on the real gas equation and thus requires measurement of the gas temperature and gas pressure. The measurement uncertainty of the hydrogen mass of the calibration standard is at most 0.4 % of the total fuelling mass or at minimum dispensing quantity (≈1 kg) of the dispenser the measurement uncertainty is 0.8 %. To achieve this low measurement uncertainty, the calibration standard has a highly accurate pressure sensor and each of the two pressure tanks has a temperature measurement tree with Pt-100 temperature sensors. Based on the determination of all influencing factors of the measurement setup as well as the environmental conditions, a corresponding evaluation model was developed with which the required mass determination and the error consideration are implemented. Several fillings of the calibration standard are carried out at public hydrogen dispensers in order to achieve a complete calibration. The recommendations of OIML R139 are followed and a calibration certificate is created with the help of the measurement results.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.

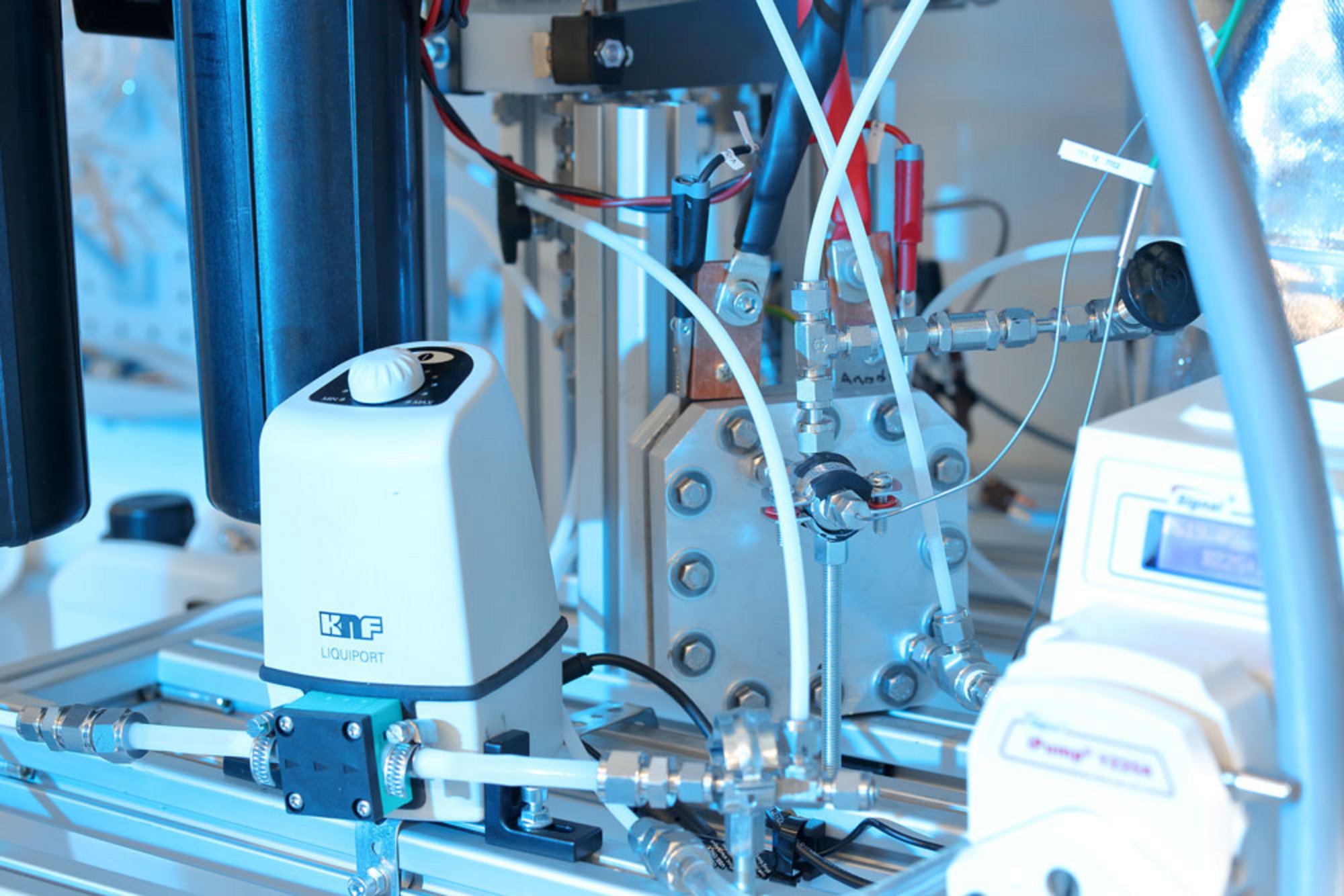

EHC electrochemical compression test stand "HERON"

The single cell test stand "HERON" (Hydrogen compression by Electrochemical Reactions withOut Noise) was designed for conducting research and development tests for electrochemical hydrogen compression (EHC) and purification cells (EHP). A test stand was integrated into the laboratory area of the test centres for the set-up and chemical preconditioning of the cells to be tested. The test stand controls the thermodynamic properties of the test sample, including the flow rate, temperatures and pressures of the supply gases. The test stand includes an electrical source and sink that allow detailed characterisation using electrochemical impedance spectroscopy. The supply media are humidified via a bubbler system before entering the test sample. The output quality of the gases can be measured in the Boltzmann laboratory via a direct connection from HERON to the FTIR and IMR-EI-MS instruments. This environment allows direct assessment of the post-cell purification performance.

Factsheet Download

Yes, I have read the data protection declaration and I consent to the data I provided being stored electronically.